Test and inspection procedures

Inspection and testing ensure high quality in the manufacturing of PCBs and electronic devices.

PCB inspection is an essential element in every electronics manufacturing process.

In a perfect manufacturing line could be produced 100% perfect assemblies.

However, even with good process controls and excellent equipment there will always be a small number of faults.

Our aim is to find all the problems before the goods leave the factory so we inspekt the whole project just bevor production stage for potential problems and offer diffrent kind of tests suitable for the projekt.

Our test methods include e.g.:

- Flying Test

- Visual check

- AOI test

- Functional Test

Not every single time all the test procedure are required!

Testing is crucial to ensure high quality products are delivered to customers. The PCB inspection and testing enables faults to be detected during and just after the manufacture process.

Many things can go wrong on a PCB.

- Components may be misaligned.

- Solder connections may not be complete.

- Excess solder can bridge circuits and cause shorts.

The Model of inspection and testing is specific to each PCB and decisions about them are often made during the PCB design.

There are various methods by which PCB inspection can be achieved.

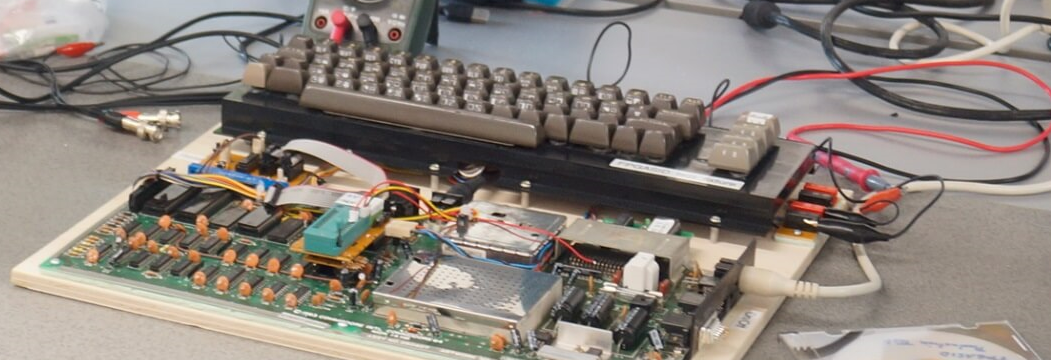

Flying Test

This is the very first electrical test before assembly for short and open circuits.

Visual inspection

Visual inspection involves individual inspectors looking at boards or other assemblies to inspect them for problems. / This approach has been proved to be costly, and yielding poor results. /

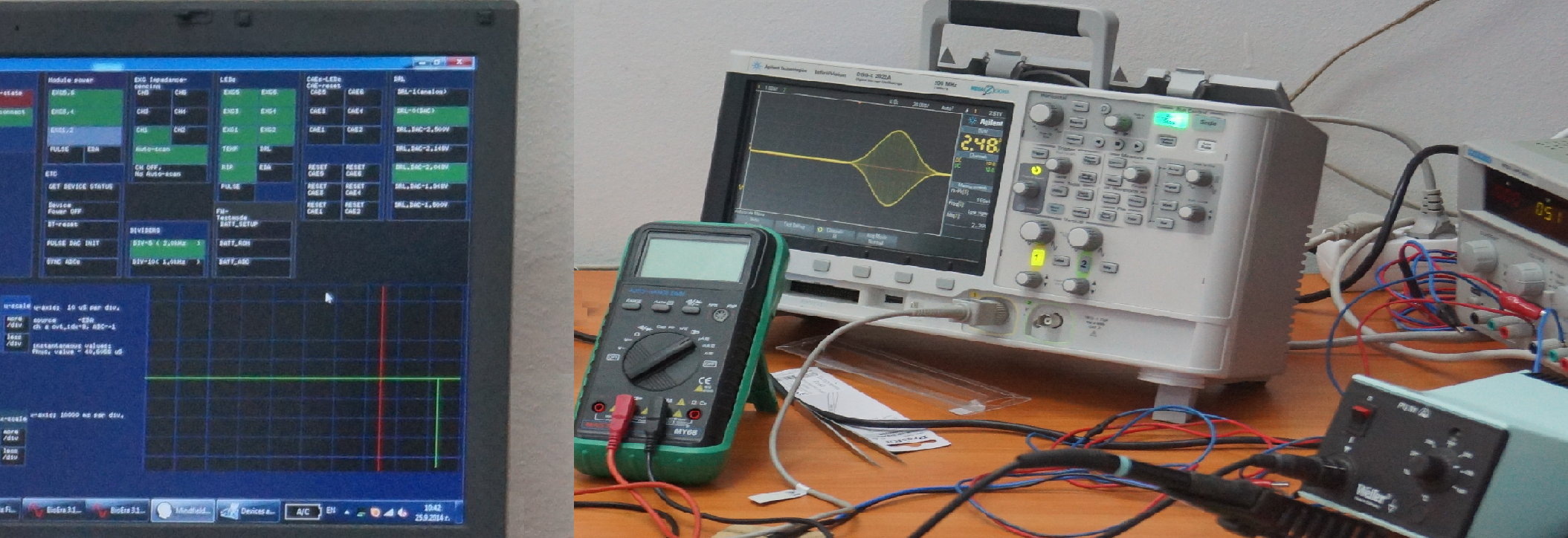

AOI check

Automatic or automated optical inspection is the preferred method of PCB inspection.

It utilises an optical system that takes an image of a good assembly and compares the two images to detect any faults or other issues.

Functional test

Flying Test, Visual inspection and AOI check are perform to identify faults during production and if the operational process is set up correctly. PCB function testing is a crucial stage prior to the integration of these boards into complete systems. We check and test the components according your specifications.

Flash Software Service

Mikrocontroller, memory chip, programmable logic, etc.

Comparison of the major defect detection capabilities of AOI and Functional Test :

| Defect type | AOI | Functional Test |

|---|---|---|

| Soldering defects | ||

| Open circuits | ||

| Solder bridges | ||

| Solder shorts | ||

| Insufficient solder | (not heel of joint) | |

| Excess solder | ||

| Solder quality | ||

| Component defects | ||

| Lifted lead | ||

| Missing component | ||

| Misaligned or misplaced component | ||

| Incorrect component value | ||

| Faulty component |

For most of the Orders our clients receive the three services Flying Test, Visual Inspection and AOI Check for free.

The cost of the functional test are not fixed and depend on complicity of the test procedure.